SuperPro Bushings are the perfect suspension replacement or upgrade solution!

SuperPro is an innovative Australian manufacturer of automotive polyurethane bushings and parts based in Brisbane, Queensland. These specially formulated, high quality components are designed to create suspension solutions for better stability, handling and control in both on and off-road applications.

In 1983, Graham Scudamore-Smith and founding company Fulcrum Suspensions embarked on the process of combining cast polyurethane with the manufacture of their very own bushes. By 1985, after ongoing problems with wear and tear of leaf spring bushes, the company started to design and produce SuperPro Bushes for the emerging 4X4 market.

SuperPro has over 40 years of experience within the suspension industry and is supported with a dedicated Research and Development Team. Like most of SuperProâÂÂs products, all our bushings are made on site in Australia. This gives SuperPro a competitive edge over all other aftermarket bushings brands. SuperPro ensures greater quality at both manufacturing and engineering endpoints, offers more advanced bushing designs, have extremely fast product turnaround, have an extensive QA process, and can get product to market much faster than all competitors.

Installing SuperPro Polyurethane Bushings into your vehicle will achieve several benefits including:

- Correcting or maintaining steering geometry of the vehicle

- Better handling

- Increased safety

- Improved tyre wear

- Improved fuel efficiency

- Enhanced vehicle performance

SuperPro Bushings are made from a proprietary polyurethane mix that has been meticulously tested and refined over 40+ years to suit AustraliaâÂÂs harshest conditions. This unique polyurethane elastomer is a class of thermosetting synthetic polymer that involves the reaction of various types of isocyanate resins with curing agents. This creates an extremely durable material with the best features of both rubber and plastic.

Since the introduction of polyurethane into the aftermarket suspension industry in the early 80s, many manufacturers have tried but few have succeeded in creating a product with consistent, accurate and durable results. SuperPro Suspension Bushes are engineered to outperform both OE designs and competitor designs. Using a team of highly skilled suspension technicians and expert engineers, SuperPro creates some of the best and most innovative suspension bushing products in the world.

SuperPro Bushings can be used in strut bars, radius rods and trailing arm locations. The use of SuperPro Bushings in these products will improve the road holding, handling and tyre wear of any passenger or 4X4 vehicle. This is possible because all SuperPro products have been designed to achieve consistent tyre to road alignment, particularly under braking and cornering loads. In many cases, there is little to no effect on NVH (noise, vibration and harshness) as a result of careful design by our Research and Development Technicians.

SuperPro has an extensive range of Poly Bushings and suspension bush kits. With an ever-increasing catalogue of quality aftermarket bushes, we have developed over 7000 designs to cater for all vehicle purposes. Our SuperPro proprietary engineering grade polyurethane formula is a superior alternative to rubber as it has been proven to be longer lasting, higher quality and quieter.

Our Bushing Design

SuperPro has over 40 years of experience within the suspension industry and are supported with a dedicated Research and Development Team. With the largest range of aftermarket bushings SuperPro have over 7000 parts, fitting well over 175,000 applications. SuperPro bushings are sold with a Lifetime Warranty that is without exception for the most part. SuperPro is also Australian manufactured, and all of our products have been tested in the harsh Australian conditions. Installing SuperPro polyurethane bushings into your vehicle will achieve several benefits including corrected or maintained steering geometry, better handling, increased safety, improved tyre wear, improved fuel efficiency and enhanced performance.

SuperPro suspension bushings are also now exported across the world, including Europe, America and Asia. All SuperPro suspension bushings are designed to suit and enhance the application it will be fitted to. The specific blend of polyurethane used in our suspension products has precise mechanical properties which allow it to be extremely resistant to abrasion, oils, and solvents and have a high tear strength. The features of polyurethane allow the design flaws in a rubber bushing to be rectified without changing the design of the suspension.

All SuperPro Bushing designs incorporate the latest technology and are created for specific applications. This enables us to produce a bushing that is a precise fit with a long product life and maintains correct steering geometry of the vehicle. The SuperPro control arm, trailing arm and lateral arm bushings are produced with a cotton-reel design. This particular design works best in these areas as it allows the primary focus of the bush to be stabilizing the movement in the vehicleâÂÂs control arms. This design also proves necessary to restrict the displacement of the bush once fitted. SuperPro have the widest range of bushes for all suspension needs of a vehicle including shackle style bushes, sway bar bushes and diff bushes. Adjustable bushes or caster off-set bushings have offset tubes to adjust Camber and Caster. In some cases, these bushings can provide Caster correction in non-adjustable suspension.

The Dual-Duro Bush is a new addition to the SuperPro range which features a softer duro center and a harder duro shell. This means when a vehicle is loaded, the bushes material is soft and pliable so no NVH is transmitted and when under loaded, the harder duro material is utilized to continue reduction in NVH.

DuroBall is another SuperPro design that is newer to the market. Our SuperPro engineers recognized many weaknesses in standard vertical pivot bushings in control arm pivot points to the chassis. This research led to the development of the DuroBall which is a unique metal and polyurethane hybrid design. This design uses the specifically formulated polyurethane blend and combines it with a specialized metal ball joint. This results in a design that provides all the benefits of a vertical pivot bush with a longer service life and greater durability. All Bushes within out SuperPro range have in-built features to ensure high performance in the desired application.

SuperPro Suspension Bushing Features

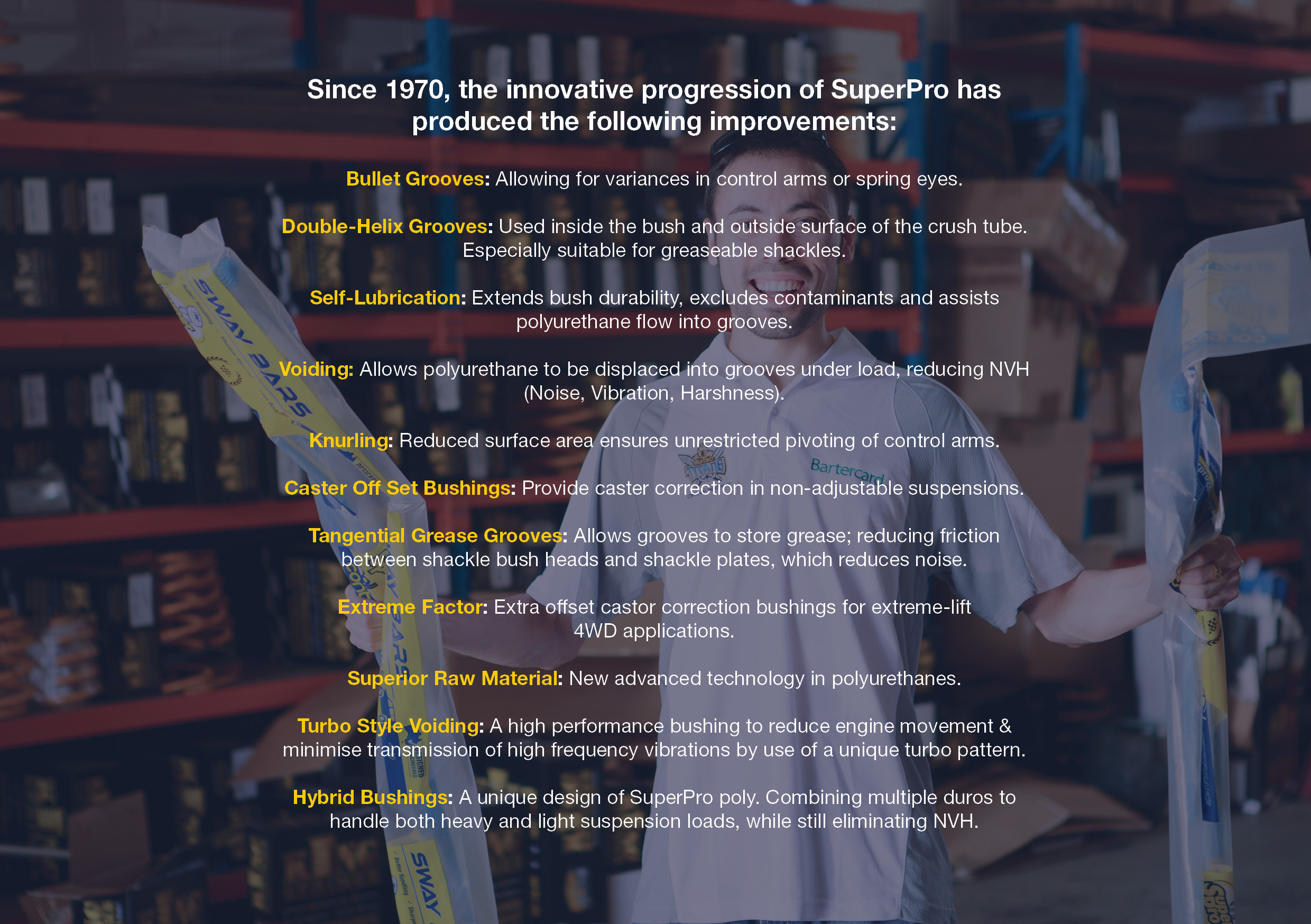

Some in-built bushing features of our SuperPro Bushes include tangential grooves, knurling, double helix grooves and bullet grooves. These features have been included in the bushing designs for grease retention and to ensure the bushings perform at the highest standard while minimizing excess NVH.

Bullet grooves allow for variances to occur in control arms or spring eyes, although polyurethane is solid when manufactured, the features of the SuperPro bushings, particularly bullet grooves, allow for the bushing to act like a liquid when loaded. This allows the bushing to prevent excessive NVH.

Knurling has several design advantages which include grease retention and a reduction in the surface area of the bushing meeting the crush tube. This results in less friction between the two components and allows unrestricted pivoting of the bushing around the crush tube and other steel surfaces.

Tangential grooves are the grease grooves in the head of the shackle bushes. This design results in reduced friction between the shackle bush head and the steel it meets, such as the shackle plates. Another advantage of the tangential grooves is it ultimately reduces noise, as the stored grease is wedged between the two surfaces that meet when the spring shackles rotate.

Double-Helix grooves are used inside the bushing and on the outside surface of the crush tube. This feature allows the grease applied to travel from the center of the bush and out into the grease grooves at the head of the bush, forming a long layer of grease.

SuperPro also uses zinc coated steel in their bushes when required to prevent rusting and ensure the longevity of the SuperPro bushing. Crush tubes are an important part of the SuperPro bushing system and are designed to make sure they are correctly fitted. In most bushings, SuperPro uses a high stress, corrosion resistant and hardnosed Supaloy material. This alloy solution is leaner and lighter, which helps lower the vehicle weight, improve fuel consumption and running costs.

What bushing material is best?

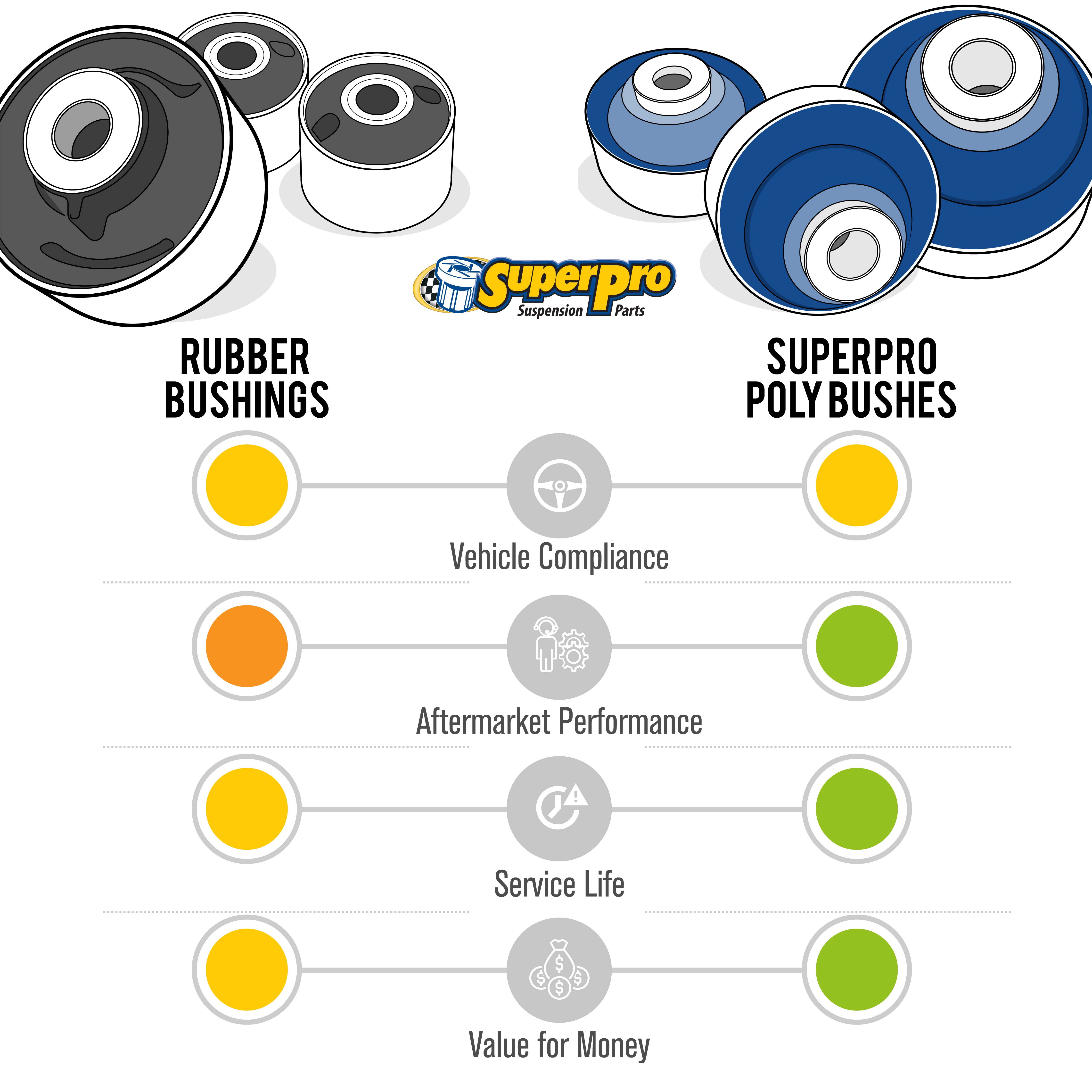

Every day in our workshops we strive to deliver the best results for our customers. We use the best equipment, the best methods, we keep our knowledge up to date and of course, we use the best replacement parts. When it comes to bushings, we know what weâÂÂre talking about. So, what kind of bushing is best? Should you use OEM styled rubber bushings or stick to your vehicle's original equipment? Or should you use SuperProâÂÂs specially engineered bushings?

What are the drawbacks of rubber bushing?

Rubber bushes are made because they are a simple and quick fix to satisfy a vehicleâÂÂs warranty requirements. However, the rubber material does have drawbacks such as a limited service life. Rubber creates voiding and elasticity which produces excessive movement, compromising tyre life and vehicle dynamics. As rubber needs to distort and deform to provide movement, the changes in geometry (alignment) are often permanent due to rubbers poor memory properties.

Another drawback of rubber is the cost. Many OE rubber bushes are not available for purchase individually and are often only available in a complete arm or assembly, even if only one bush needs replacing.

Why SuperPros bushing material is the best!

One of the many benefits of using aftermarket components is that each product is built from scratch. This guarantees the product will exceed standards as a standalone component, rather than as a subordinate component of a larger module as seen in OE engineering. SuperPro embraces the concept of developing a higher quality, noise reduced, longer lasting alternative to standard rubber bushings.

SuperPro bushings are engineered with a proprietary polyurethane. Polyurethane is a special elastomer-based material which gives an extremely durable suspension product featuring the best characteristics of both rubber and plastic. With extensive application products ranging from hard plastics to carpet underlay, SuperPro have developed a unique polyurethane formulation exclusively for use as suspension bushing material. This has resulted in superior mechanical properties to rubber including:

- Superior abrasion resistance

- Excellent memory properties

- Unaffected by extreme temperature, oils and coolant

- Superior control of noise, vibration and harshness (NVH) equal or exceeded OE.

- Not constrained by OE design constraints (mass-production costs, warranty and vehicle assembly factors)

Vertical Pivoting Bushings

The vertical pivoting bush (VPB) is a perfect example in expressing the contrasting performance between OE rubber and poly bushings. This style of bushing was introduced by manufacturers to increase factory efficiency and reduce costs in the assembly of the under carriage and engine modules. The tradeoff is an unfortunate tendency for distortion under high lateral loads and excessive lateral movement of the control arm. Although these original rubber VPB mounts provide a cost-effective mounting solution, in most applications they result in a short service life.

In response to this latent issue, SuperPro polyurethane VPB bush designs ensure that the control arm is positively located in all situations with increased freedom to articulate as intended. This results in a vehicle that brakes safely and predictably, maintaining wheel alignment under all conditions and maximizing your tyre life.

Lifetime Warranty

All SuperPro products are engineered in Australia and are Built to last. This is backed by the lifetime warranty offered by SuperPro for all their bushings.

All SuperPro Suspension Bushings, Sway Bars and Suspension Arms are covered by a Lifetime Warranty. This means that if a SuperPro Product fails, it will be replaced free of charge without exception. SuperPro will also replace any brand of automotive Polyurethane Bushing, which has failed due to factory defects in material and/or workmanship as determined by SuperPro with our own product for free.

Click here to see our Latest Products!

Click here to visit Tradeview to see what products are available for your car!